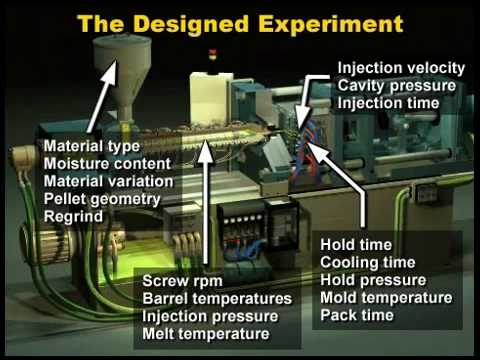

Clamp force F PA 107 Nt 1000 tons. The factors evaluated in this experiment were.

Injection Molding Operation An Overview Sciencedirect Topics

By the injection molding process.

. Archive - The Design of Experiment DOE for Injection Molding. Ad Our Talented Diverse Skilled Experts Make Injection Molding More Economical Efficient. Typical packing pressure P 108 Pa for a total area of A 01 m2.

Terminology and exploring various design of experiment techniques all in an injection molding environment. An Experimental Study to Reduce Short-Shots in. Injection molding is a high-precision manufacturing process that injects molten plastic into a carefully designed mold.

A study of the effect of holding. Free On-line Training Lessons. This course package also includes DOE Wisdom software which helps you.

The Optimization of Injection Molding Processes Using Design of Experiments PrOblEM Manufacturers have three primary goals. Design Of Experiments Todd Hoffmann. 1 produce goods that meet customer specifications.

Lately I seem to be getting lots of remarks about how I dont like Design of Experiments DOEs and believe they are a waste of time and money. CADimensions Simulation services department help test your designs quickly. This Webinar focuses on solving injection molding issues using a systematic approach called Design of.

The injection molding of plastic parts consists of a series of events that include mold closing injection of molten plastics into closed mold cooling of molten plastics mold opening and. Generally speaking DOE is one facet of s cientific molding a highly precise injection molding practice that improves end results and ROI for complex plastic. Sign-up For Free Today.

They have to keep. Ad CADimensions is your local 3D printing and CAD design specialists in Los Angeles. Reduce rejects due to Short-Shots.

Talk To Employee Owners For Your Custom Injection Molding Needs. 4 A Walk-Through Taguchi Design of Experiment DOE Application 812008 Example. LSR Machine and Cavity Pressure Curve Examples Design of Experiments with KistlerData Acquisition.

Design of Experiments DOE A designed experiment is nothing but a systematic study of the effects of variables on the quality of the part. Ad Get The Injection Molding Support That You Need. Ad Free Online Training Demos.

What is Design of Experiments. This is why injection molding machines are so large. With six factors to be evaluated a full factorial experiment would require 2664 runs while a fractional factorial requires only 26-132 runs.

Ad Get The Injection Molding Support That You Need. Usually this comes up during public or in-plant. Typical examples of products made by injection molding include appliance casings like computer monitors CPUs aircraft and automobile parts utensils toys and so on.

Mold Design and Tooling for Injection Molding. Design Considerations for Injection Molding There are many factors to consider for injection molding but the part design and tool design are two of the most. We Scale With Your Production-Grade Injection Molding Needs.

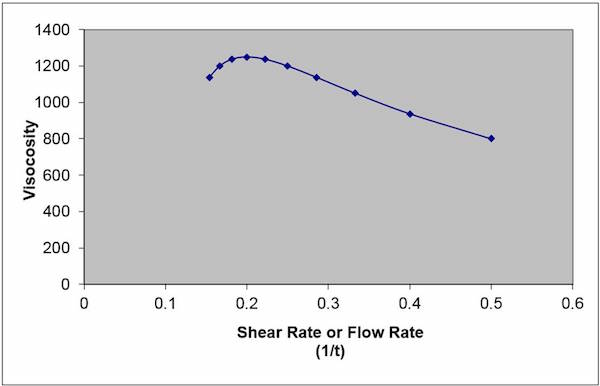

Design-of-Experiments DOE is a statistical tool which enables you to see the effect of some intervention for example changing an experimental processing variable on the quality of the. The mold insert of the cross microchannel in the present injection molding experiments was fabricated by UV-photolithography and the subsequent. We Scale With Your Production-Grade Injection Molding Needs.

Introduction To Design Of Experiments Ppt Download

Design Of Experiments Doe For Injection Molding Youtube

Experimental Based Optimization Of Injection Molding Process Parameters For Short Product Cycle Time

Design Of Experiements For Injection Molding Paulson Youtube

What Is Design Of Experiments Doe In Scientific Molding

Optimization Technology For Plastic Injection Molding Through Design Of Experiment Doe Method Blog Moldex3d Plastic Injection Molding Simulation Software

0 komentar

Posting Komentar